Shandong Jiayi Machinery Sheet Metal Equipment Manufacturing Base

+86 137-0538-4901 +86 189-5381-3118 |

Shandong Jiayi Machinery Sheet Metal Equipment Manufacturing Base

+86 137-0538-4901 +86 189-5381-3118 |

Product

產品展示

GP MINI Press brake

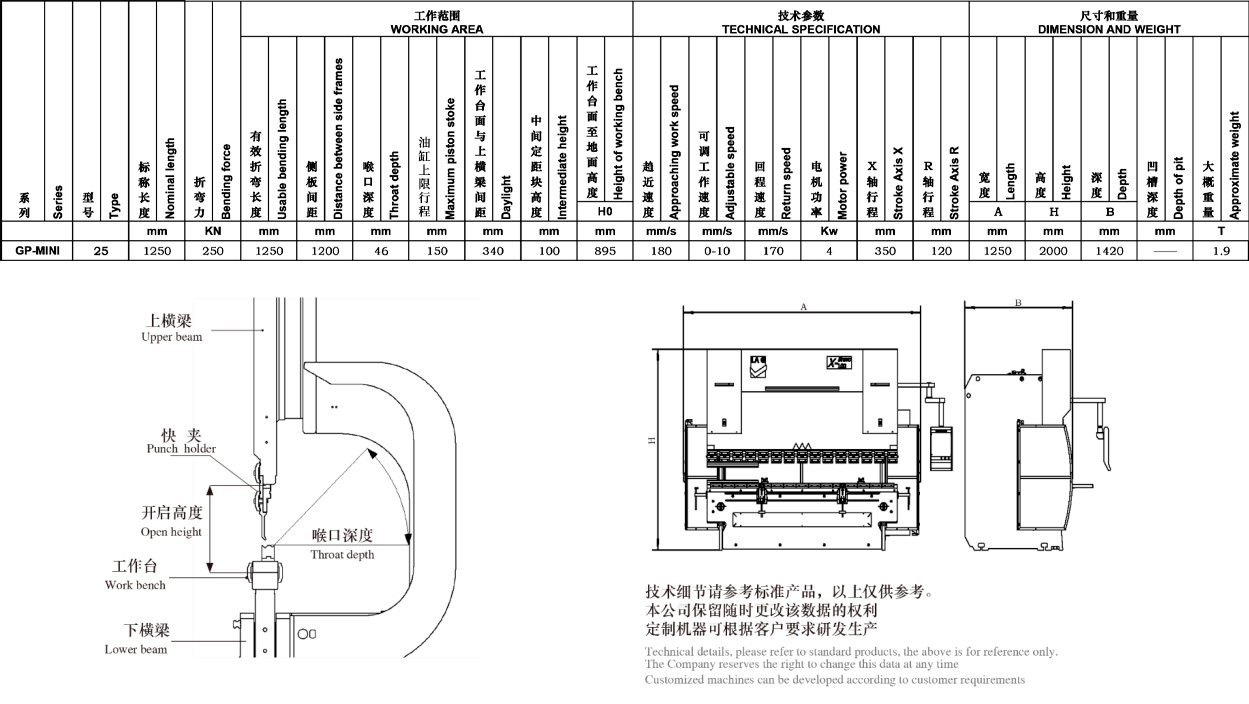

The GP MINI series has a unique compact design hydraulic system to ensure the speed and stability of the double cylinder driven upper beam during the downward process. GP MINI bending machines are versatile and can be used not only for small sheet parts, but also for medium sized parts of thick plates, which can achieve high production efficiency for small batch or large batch bending, and is a cost-effective solution for sheet metal processing.

? Energy saving, 2.2kw motor, pressure holding function under stable pressure to effectively overcome the elastic deformation of metal materials, energy saving bending model;

? High flexibility, unique exquisite single-arm C-frame fuselage design, 15 tons of pressure, downward operating mode, adjustable starting point and other features fully reflect the flexibility of production operations, is the production center of small parts bending;

? Genuine, small GP bending machine body has the main features of large bending machine. There are two main models: MINI GP515 and MINI GP815, which can be upgraded to CNC bending and robot integrated bending.

? High accuracy, bending repeatability can reach 0.5 degrees/meter

? Strong reliability, the whole machine imported from Italy, strong steel fuselage support, the integration of hydraulic components and control components from world manufacturers, equipment stability, long service life;

? Friendly operation, the parallelism of the bending tool, DBC and bending Angle can be adjusted in real time according to the numerical reader, one time completion, no need to repeat the sample, 2 minutes to complete the bending Angle setting.

? 3-axis servo CNC system, Y-axis, x1, -x2, the whole CNC bending process to complete the multi-channel bending of the workpiece, fast rise, bending efficiency. Slow fitting of the workpiece and pressure process ensure accurate positioning of the workpiece, operation, flexible application of working pressure, reduce impact, X1, X2 real-time positioning accurate;

Maintain pressure to overcome elastic deformation of metal materials;

? Unloading, flexible unloading to reduce the rigid impact of the operation process, ensure;

? Fast return, bending efficiency

Production efficiency is not only the goal pursued by sheet metal processing factories, but also the direction that bending machine manufacturers are working hard every day. The growing personalized demand makes the shortage of skilled workers, the cost of labor continues, the product design is becoming more and more complex, and the batch scale is getting smaller and smaller. Being aware of these issues and knowing how to deal with them is crucial. GP MINI25 bending machine optimize the system and mold in all aspects, so that you can immediately enjoy the advantages brought by LAG;

? Large 200mm/s upper beam approach speed and 600mm/s rear stopper X-axis speed and acceleration

? Friendly touch screen operation interface, two-dimensional graphical simulation of bending, LED bending process display, open up a wide range of bending applications

Low noise, high operability ergonomic design structure, flexible section mold combination installation mode

? Compact modern design, the use of metal sheet bending structure of the back stop and stainless steel front support, improve bending speed and stability

? Small footprint, only with forklift can be moved and put into use within 5 minutes.

ESA 630 touch screen numerical control system

In cooperation with ESA, the world's leading manufacturer of numerical control systems, LAG has configured the ESA 630, a numerical control system that combines modern electronic information control technology with the application technology of the bending machine industry, making it easy for operators to quickly implement programming, calibration and bending in a variety of different shapes and conditions

ESA630 adopts modern technology of 10-inch touch screen design, WindowsXP operating system, can also be external keyboard, mouse operation, bringing a great improvement in the data input experience, programming time is also greatly shortened most bending workpiece can be programmed through two-dimensional graphics, two-dimensional automatic simulation bending, automatic generation of bending steps. Even beginners can do the bending work quickly

2D offline programming software

All GP MIN series of bending machines can be designed in the office for bending simulation, developing material calculation and other design work with standard 2D off-line programming software

GP-M CX-R) rear stop shaft linkage

As a guarantee of the dimensional accuracy of the bending product, the back stop system is another component of the bending machine. The 2-axis (X-R) rear stopper of the GP-mini standard ensures flexible, high-speed positioning of nearly all complex bending workpieces. 2 stops are standard, with more stops available.

Protective device

The fully closed transparent rear protective door structure that can be rotated and opened, while realizing the compact characteristics

Manually slide the front bracket

The highly rigid Ricijin bending structural front bracket is easily sliding left and right by hand along the linear guide in the Z-axis direction through the roller support.

Die fixture

Innovative "two ways to take the mold" quick clip. Standard with Japan Xu light H=100mm high-precision manual single-sided quick clip, no wrench, just fingers easily snap the handle with two gears, free to choose to replace small segment mold or longer mold, compatible with European, Japanese and domestic mold handle structure clamping, a person can be convenient and fast from the side or bottom of the fast clip quick tool change.

Die clamp G-Block M

LAG manual self-centering fixture, no need to adjust the upper die automatically when changing the lower die, no need to adjust the upper and lower die

Modular die system

The segmented dies and diversified die combinations after grinding are convenient for users to use and replace

According to the part drawing of the bending product you need and the thickness of the commonly used sheet material, LAG engineers will recommend the selection of bending molds according to the opening height and bending force of the bending machine.

Main standard configuration

Numerical control system ESA S630

4-axis (Y1-Y2-X-R)

Rear stop GP-M(X-R)

Two back stop fingers

CE standard (double gear) foot switch

Telephonee:

+86 13705384901

Build Geshi international technology brand

CONTACT US

Tel:+86 13705384901 +86 18953813118 +86 0538-6089096 +86 0538-6089189

E-mail:[email protected]

Add:South of Kuixing Road, north of Xingfu Road, Ciyao Town, Ningyang County, Tai'an City, Shandong Province, China